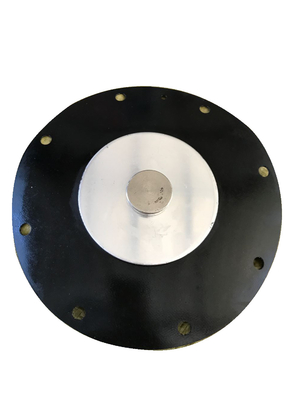

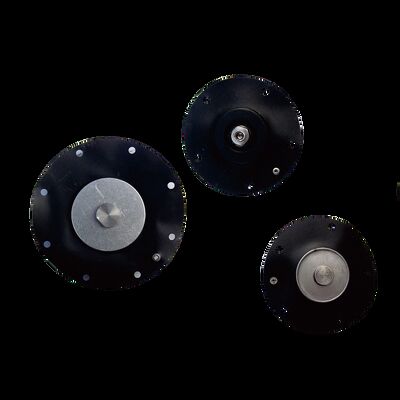

Descrição do Produto:

A Válvula Solenoide Diafragma é um componente de precisão projetado para oferecer desempenho e confiabilidade excepcionais em diversas aplicações de controle de fluidos. Especificamente projetada para uso com sistemas hidráulicos, máquinas de café e configurações pneumáticas, esta membrana é uma parte essencial dos conjuntos de válvulas solenoides, garantindo uma operação suave e durabilidade de longa duração. Seu design incorpora um tipo de instalação aparafusada, tornando-a fácil de instalar e substituir sem comprometer a integridade do sistema.

Uma das características de destaque desta Válvula Solenoide Diafragma é sua compatibilidade com bobinas solenoides, incluindo a amplamente utilizada Bobina de Válvula Solenoide Hidráulica. O tipo de bobina usado nesses sistemas é solenoide, o que permite o controle rápido e preciso do fluxo de fluido quando energizado eletricamente. Isso torna a membrana uma escolha ideal para aplicações que exigem regulação precisa de fluidos, como em válvulas solenoides de máquinas de café, onde o desempenho consistente é fundamental para a qualidade da preparação do café. A capacidade da membrana de funcionar perfeitamente com essas bobinas aumenta a capacidade de resposta e a confiabilidade da válvula.

Com um tamanho de orifício de 3/4 de polegada, esta membrana é perfeitamente adequada para aplicações de fluxo médio. O orifício de 3/4 de polegada permite a passagem eficiente de fluido, mantendo o controle sobre a pressão e as taxas de fluxo, o que é essencial em sistemas hidráulicos e pneumáticos. Este tamanho encontra um equilíbrio entre design compacto e capacidade de fluxo suficiente, tornando a membrana versátil para vários usos industriais e comerciais.

A resistência à corrosão é um atributo vital para qualquer componente de válvula exposto a fluidos, e esta Válvula Solenoide Diafragma se destaca nessa área com suas propriedades de alta resistência à corrosão. Construída com materiais que resistem a ambientes agressivos, a membrana resiste à degradação por produtos químicos, umidade e outros agentes corrosivos. Isso a torna particularmente adequada para aplicações como máquinas de café, onde a exposição à água e agentes de limpeza é frequente, bem como para sistemas hidráulicos que operam em condições adversas. A maior resistência à corrosão contribui para uma vida útil mais longa e reduz a necessidade de manutenção ou substituição frequente.

A membrana é projetada para operar com eficiência em uma faixa de temperatura de -20°C a 80°C. Essa ampla tolerância de temperatura garante um desempenho confiável em diversos ambientes, desde instalações de armazenamento a frio até ambientes industriais mais quentes. A capacidade de manter a flexibilidade e a capacidade de vedação em toda essa faixa de temperatura é crucial para manter a integridade do sistema e evitar vazamentos ou falhas. Seja usado em uma Válvula Solenoide Pneumática de 2 Vias ou em uma válvula solenoide de máquina de café, a resiliência da temperatura da membrana garante uma operação consistente sem compromisso.

Além disso, a compatibilidade da Válvula Solenoide Diafragma com Válvulas Solenoides Pneumáticas de 2 Vias destaca sua versatilidade no controle do fluxo de ar em sistemas pneumáticos. Essas válvulas são comumente empregadas em processos de automação e controle, onde a capacidade de resposta e a durabilidade da membrana impactam diretamente a eficiência do sistema. O tipo de instalação aparafusada facilita a manutenção e substituição rápidas, minimizando o tempo de inatividade e garantindo a operação contínua em aplicações críticas.

Em resumo, esta Válvula Solenoide Diafragma oferece uma solução robusta para as necessidades de controle de fluidos em vários setores. Seu tipo de instalação aparafusada simplifica a integração e a manutenção, enquanto a compatibilidade da bobina solenoide garante uma operação precisa e responsiva. O tamanho do orifício de 3/4 de polegada oferece um equilíbrio ideal entre capacidade de fluxo e controle, tornando-o adequado para aplicações hidráulicas, pneumáticas e máquinas de café. A alta resistência à corrosão aumenta a durabilidade em ambientes desafiadores, e a ampla faixa de temperatura de -20°C a 80°C garante um desempenho confiável em condições variáveis. Se você está procurando otimizar um sistema de Bobina de Válvula Solenoide Hidráulica, aprimorar uma Válvula Solenoide de Máquina de Café ou melhorar a funcionalidade de uma Válvula Solenoide Pneumática de 2 Vias, esta membrana foi projetada para atender e superar as expectativas, fornecendo um serviço eficiente, confiável e duradouro.

Características:

-

Nome do Produto: Válvula Solenoide Diafragma

-

Princípio de Funcionamento: Operado por Piloto

-

Faixa de Pressão: 0 a 10 Bar

-

Tensão de Operação: 12V / 24V / 110V / 220V (dependendo da Válvula Solenoide)

-

Pressão de Trabalho: 0-10 Bar

-

Compatível com aplicações de Válvula Solenoide de Suspensão Pneumática

-

Adequado para sistemas de Válvula Solenoide de Máquina de Café

-

Diafragma durável garantindo desempenho confiável em operações de Válvula Solenoide de Máquina de Café

Parâmetros Técnicos:

|

Tipo de Instalação

|

Aparafusado

|

|

Espessura

|

1,5 mm

|

|

Faixa de Temperatura

|

-20°C a 80°C

|

|

Faixa de Pressão

|

0 a 10 Bar

|

|

Tipo de Bobina

|

Solenoide

|

|

Princípio de Funcionamento

|

Operado por Piloto

|

|

Material

|

NBR (Borracha Nitrílica Butadieno)

|

|

Vedação

|

Boa Vedação

|

|

Material do Diafragma

|

Borracha Nitrílica

|

|

Tamanho do Orifício

|

3/4 Polegada

|

Aplicações:

A Válvula Solenoide Diafragma HONGUM é um componente essencial projetado para uso em diversas aplicações industriais e comerciais onde o controle confiável de fluidos é fundamental. Especificamente projetada para caber nas Válvulas Pneumáticas ASCO Solenoid Valve com um tamanho de orifício de 3/4 de polegada, esta membrana garante o desempenho ideal em sistemas de Válvula Solenoide Pneumática de 2 Vias. Sua alta resistência à corrosão a torna ideal para ambientes expostos a produtos químicos agressivos ou umidade, prolongando a vida útil da válvula solenoide e reduzindo as necessidades de manutenção.

Uma das principais ocasiões de aplicação para a membrana HONGUM é em sistemas de suspensão pneumática, onde a Válvula Solenoide de Suspensão Pneumática requer operação precisa e consistente para manter a estabilidade e o conforto do veículo. As excelentes propriedades de vedação da membrana evitam vazamentos e garantem a atuação suave da válvula, o que é crucial para manter a integridade dos circuitos pneumáticos em sistemas de suspensão automotiva.

Além disso, esta membrana é adequada para uso em várias configurações de Válvula Solenoide Pneumática de 2 Vias em setores como tratamento de água, sistemas HVAC, irrigação agrícola e automação pneumática. Sua compatibilidade com múltiplas tensões de operação (12V, 24V, 110V e 220V), dependendo do modelo da válvula solenoide, permite que ela seja integrada facilmente em diferentes configurações elétricas, aumentando sua versatilidade.

Em fábricas, a Válvula Solenoide Diafragma HONGUM é frequentemente empregada em sistemas de controle pneumático onde a regulação precisa do fluxo de ar é necessária. As capacidades de vedação robustas da membrana evitam a contaminação e garantem o controle consistente da pressão, o que é vital para máquinas automatizadas e controle de processos. Além disso, sua alta resistência à corrosão permite que ela funcione de forma confiável em ambientes com exposição a gases ou fluidos corrosivos.

No geral, a membrana HONGUM desempenha um papel crítico no aprimoramento da funcionalidade e durabilidade das Válvulas Solenoides Pneumáticas de 2 Vias e das Válvulas Solenoides de Suspensão Pneumática. Seja em sistemas de suspensão pneumática automotiva, circuitos pneumáticos industriais ou outras aplicações de controle de fluidos, esta membrana garante uma operação eficiente e sem vazamentos sob condições de tensão variáveis e fatores ambientais desafiadores.

Suporte e Serviços:

Nosso produto Válvula Solenoide Diafragma é suportado por uma equipe de suporte técnico dedicada, comprometida em garantir o desempenho e a longevidade ideais de seus equipamentos. Fornecemos orientação abrangente de instalação, assistência na solução de problemas e dicas de manutenção para ajudá-lo a obter uma operação perfeita.

Além do suporte técnico, oferecemos uma gama de serviços, incluindo personalização de produtos, peças de reposição e serviços de reparo para atender às suas necessidades específicas de aplicação. Nossos especialistas estão disponíveis para auxiliar na integração do sistema e fornecer recomendações para aumentar a eficiência e a confiabilidade.

Também fornecemos documentação detalhada, incluindo manuais do usuário, fichas de dados e FAQs, para ajudá-lo a entender os recursos e especificações do produto. Atualizações regulares e boletins técnicos estão disponíveis para mantê-lo informado sobre os últimos avanços e melhores práticas.

Nosso objetivo é fornecer suporte e serviços excepcionais que permitam que você maximize o desempenho de sua Válvula Solenoide Diafragma e garanta o sucesso operacional sustentado.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!